Single-channel loading magazine

Optimised for medium and large-scale production

SiMag

Application area:

- Ideal for medium to large-sized batches

Properties:

- Short changeover times, easy handling

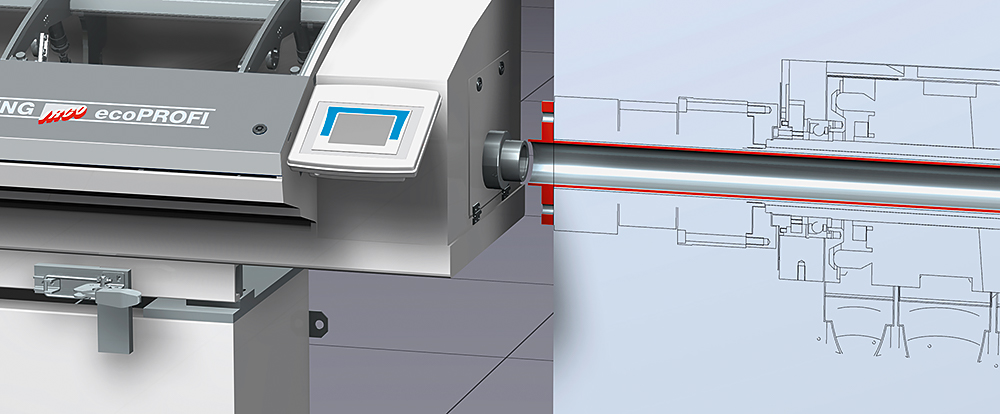

- Extremely smooth running, hydrodynamic bearing, 360° closed guide channels

- High operating comfort thanks to a 18 cm (7″) widescreen touch display

- Process-reliable supply of rotationally symmetrical profile material

- Suitable for long turners (optional) electronic synchronizing device, optimal material guidance up to the clamping device with a telescopic system

- Easy conversion from long to short turning mode at the touch of a button

Working range:

- Round material, diameters from 5 to 130 mm

- Bar length 3200 mm, 4200 mm and 6200 mm (10000 mm)

Special features:

- Easy replacement of the spindle liner tubes through an axial slide of the magazine (optionally radial swivel-out)

- Process-integrated remnant disposal through the machine (optionally by the magazine)

- Machine-protection, vibration-absorbing design; easy replacement of the spindle liner tubes thanks to radial slide of the magazine (optionally axial slide)

Hydrodynamic bar guiding

Automatic disposal of the bar remnant by optional remnant retraction

Optional: Centering steady rest between guide channel and spindle filler tube

Two-part guide segment with clip fastening

Combination steady rest with rollers for round material Ø > 23 mm

Combination steady rest with jaws for profile and round material Ø < 23 mm

In order to optimize your manufacturing process we are happy to customize the loader to your respective operational situation. Thanks to the modular construction of our serial products we are able to cover a large number of application scenarios, thus combining the highest-possible quality in the series with highly specific, individual solutions.

Geometries to be processed:

Further geometries upon request: